Not all photovoltaic power plants have the same 発電 efficiency. How can photovoltaic power plants improve power generation efficiency? Apart from factors such as the amount of solar radiation and the inclination angle of photovoltaic cell modules, what are the influencing factors? details as following:

The amount of solar radiation

When the conversion efficiency of photovoltaic cell modules is constant, the 発電 of photovoltaic systems is determined by the intensity of 太陽 radiation. Under normal circumstances, the utilization efficiency of solar radiation by photovoltaic systems is only about 10%. So take into account the intensity of solar radiation, spectral characteristics, and climate conditions.

The tilt angle of the photovoltaic cell module

The azimuth angle of photovoltaic modules is generally selected in the south direction, so as to maximize the 発電 per unit capacity of the photovoltaic power station. As long as it is within ±20° of due south, it will not have much impact on power generation. If conditions permit, it should be 20° southwest as far as possible.

PV Module Efficiency and Quality

Calculation formula: theoretical 発電 = total annual average solar radiation * total battery area * photoelectric conversion efficiency, there are two factors in the battery area and photoelectric conversion efficiency, the conversion efficiency has a direct impact on the 発電 of the power station.

Component matching loss

Any series connection will cause current loss due to component current differences, and any parallel connection will cause voltage loss due to component voltage differences. Losses can reach more than 8%. In order to reduce the matching loss and increase the power generation capacity of the 発電所, the following aspects should be paid attention to: 1. To reduce the matching loss, try to use the components with the same current in series; 2. The attenuation of the components should be as consistent as possible; 3. The isolation diode.

temperature (ventilation)

Some data show that when the temperature rises by 1°C, the maximum output power of the crystalline silicon photovoltaic module group decreases by 0.04%. Therefore, it is necessary to avoid the influence of temperature on 発電 and maintain good ventilation conditions.

The loss of dust should not be underestimated

The panel of the crystalline silicon module is tempered glass, which is exposed to the air for a long time, and organic matter and a lot of dust will naturally accumulate. The dust on the surface blocks the light, which will reduce the output efficiency of the module and directly affect the power generation. At the same time, it may also cause the “hot spot” effect of the components, resulting in damage to the components.

Shadow, snow cover

In the process of site selection of the 発電所, attention must be paid to the shielding of the light. Avoid areas where light occlusion may occur. According to the circuit principle, when the components are connected in series, the current is determined by the least block, so if there is a shadow on one block, it will affect the 発電 of the components. Likewise, winter snow should be removed in time.

Maximum Output Power Tracking (MPPT)

The MPPT efficiency is a key factor in determining the 発電 of a photovoltaic inverter, and its importance far exceeds the efficiency of the photovoltaic inverter itself. MPPT efficiency is equal to hardware efficiency multiplied by software efficiency. The hardware efficiency is mainly determined by the accuracy of the current sensor and the sampling circuit; the software efficiency is determined by the sampling frequency. There are many ways to implement MPPT, but no matter which method is used, first measure the 力 change of the component, and then react to the change. The key component is the current sensor, its accuracy and linearity error will directly determine the hard efficiency, and the sampling frequency of the software is also determined by the accuracy of the hardware.

Reduce line losses

In a photovoltaic system, cables account for a small part, but the influence of cables on 発電 cannot be ignored. It is recommended that the line loss of the DC and AC circuits of the system be controlled within 5%. The cables in the system should be done well, the insulation performance of the cable, the heat and flame retardant performance of the cable, the moisture-proof and light-proof performance of the cable, the type of the cable core, and the size of the cable.

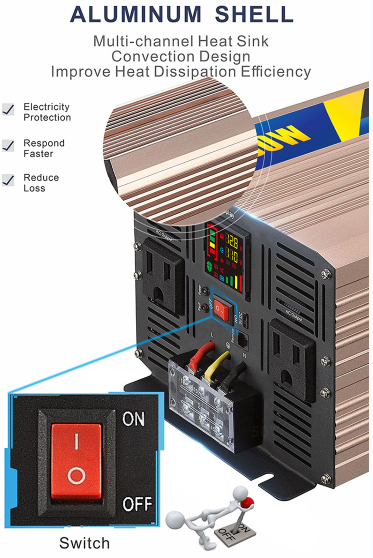

Inverter efficiency

The photovoltaic inverter is the main component and important component of the photovoltaic system. In order to ensure the normal operation of the 発電所, the correct configuration and selection of the インバーター is particularly important. In addition to the configuration of the inverter according to various technical indicators of the entire photovoltaic power generation system and referring to the product sample manual provided by the manufacturer, the following technical indicators should generally be considered: 1. Rated output 力 2. Adjustment performance of output voltage 3 , Machine efficiency 4. Start-up performance.

mylion inverter link:https://myliontech.com/product/mylion-6000w-power-inverter-usb-dual-ac-outlet-6kw-car-chargerprofessional-grade-power-inverter-fast-charge-for-solar-system/