As the testing center of the entire power station, the inverter is connected to the DC components on the top and the grid-connected equipment on the bottom. Basically, all the parameters of the power station can be detected by the inverter. Generally, as long as the inverter is connected to the grid, the power curve displayed by the monitoring is a normal “mountain” line, which proves that the power station is running stably. If there is an abnormality, you can check the health status of the supporting equipment of the power station through the information fed back by the inverter. Below are some common fault information and processing methods of photovoltaic inverters:

1. Low insulation resistance: use the exclusion method. Unplug all the strings on the input side of the inverter, and then connect them one by one. Use the function of the inverter to start up to detect the insulation resistance to detect the faulty strings. After finding the faulty strings, check whether the DC connectors are flooded with short-circuit brackets. Or burn the short-circuit bracket, and also check whether the component itself has black spots on the edge burned out, causing the component to leak electricity to the ground grid through the frame.

2. Low bus voltage: If it occurs in the morning/evening period, it is a normal problem because the inverter is trying to limit the power generation conditions. If it occurs in normal daytime, the detection method is still the exclusion method, and the detection method is the same as item

3. Leakage current fault: The root cause of this type of problem is the installation quality problem, which is caused by choosing the wrong installation location and low-quality equipment. There are many failure points: low-quality DC connectors, low-quality components, substandard installation height of components, low-quality grid-connected equipment or water leakage and electricity leakage. Good insulation work solves the problem, if it is a provincial problem of the material, you can only replace the material.

4. DC overvoltage protection: As components pursue high-efficiency process improvement, the power level is constantly updated and increased, and the open-circuit voltage and operating voltage of components are also rising. The temperature coefficient must be considered in the design stage to avoid overvoltage at low temperature. damage.

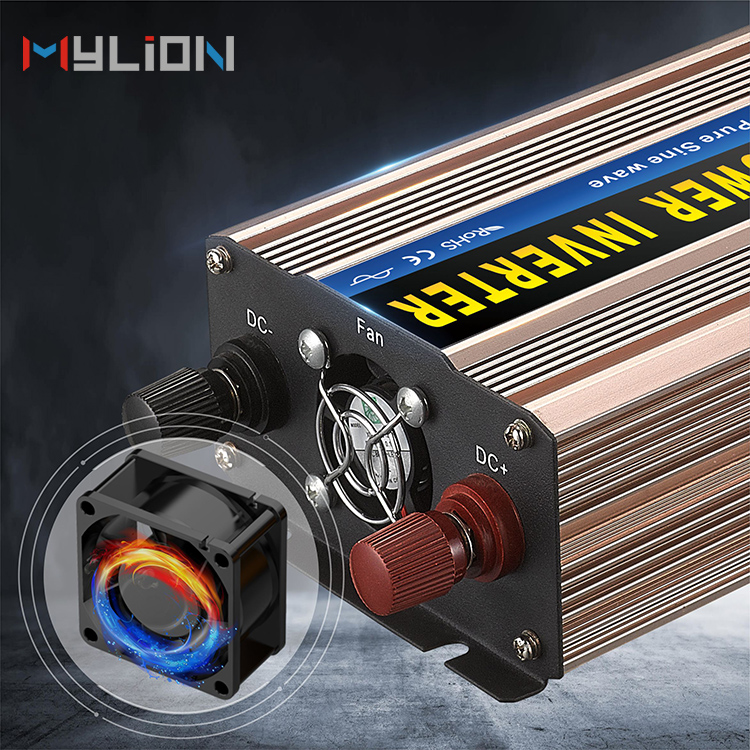

5. There is no response when the inverter is turned on: please make sure that the DC input line is not reversed. Generally, the DC connector has a foolproof effect, but the crimping terminal does not have a foolproof effect. Read the inverter manual carefully to ensure that the positive and negative poles are crimped. very important. The inverter has built-in reverse short-circuit protection, and it starts normally after the normal wiring is restored.

6. Power grid failure:

Grid overvoltage: The work of early-stage investigation of power grid heavy load (large power consumption working time)/light load (less power consumption rest time) is reflected here. The technical combination of communicating the grid situation can ensure that the project design is within a reasonable range, and do not “take it for granted”, especially in rural power grids, the inverter has strict requirements on grid-connected voltage, grid-connected waveform, and grid-connected distance. The main reason for the occurrence of grid overvoltage problem is that the light load voltage of the original grid exceeds or is close to the safety protection value. If the grid-connected line is too long or the crimping is not good, the line impedance/inductive reactance is too large, and the power station cannot operate normally and stably. The solution is to find the power supply bureau to coordinate the voltage or correctly select the grid connection and strictly control the construction quality of the power station.

Grid undervoltage: This problem is the same as that of grid overvoltage, but if the voltage of an independent phase is too low, in addition to the incomplete load distribution of the original grid, the power failure or circuit break of the phase grid will also cause this problem. virtual voltage. Power grid over/under frequency: If such problems occur in the normal power grid, it proves that the health of the power grid is very worrying. There is no voltage in the grid: check the grid-connected line.

Power grid phase loss: Check the phase loss circuit, that is, no voltage line.

7. The last point-monitoring lap joint: Correctly read the equipment manual, model line crimping, equipment connection, and set the communication address and time of the equipment, which is a guarantee to ensure stable and effective communication!

8. Power generation guarantee: when you have time to wipe the board, the power generation will “convex” and it will rise.